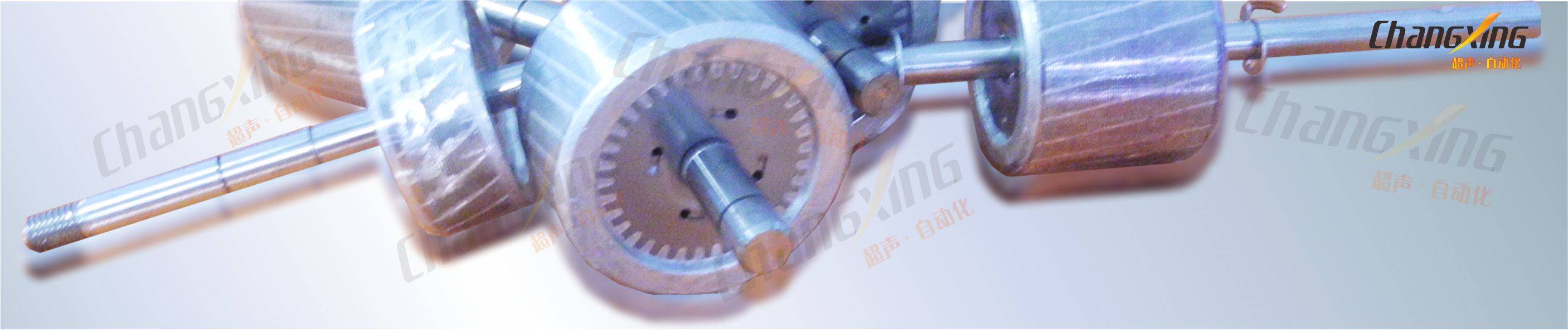

Bearing industry

Cleaning products: Various bearing parts

Cleaning material:

Dust grains, oil stains, etc

Cleaning requirements:

The removal of grease and oil from stainless steel bearings in the absence of CFCs can be as clean as any used solution cleaning.

Previous cleaning methods:

Use trichloroethane for solvent or steam cleaning

Recommended processing methods:

- bearing horizontal submerged in 40 KHZ heating type ultrasonic cleaning groove 5 minutes, groove in 52 ° C temperature containing aqueous solution, using high concentration solution.

- within 66 ° C hot water, 90 seconds, rinse thoroughly with ultrasonic overflow velocity of 0.3 GPM, sewage into the can make the dirt or separation of the hydrocarbon and water separation tank.

- in 71 ° C hot water, the three cascade tank rinse for 3 minutes, velocity of 1.5 GPM.

- with air knife blow, with blowing hot air dryer to dry, then drying temperature of 116 ° C

Cleaning system:

Semi-water agent or continuous cleaning equipment with dryer

Technology advantage:

- enhances the ability to clean the dirt of ions and organic matter

- no need to change the oils or lubricants that are currently being applied in the manufacturing process

- better process control - simple processing techniques without complex monitoring

- good for the environment - separating organic dirt and hydrocarbons from sewage, effectively maintaining the equipment

position:home>Market Application

position:home>Market Application