Application of plastic welding technology in automobile industry

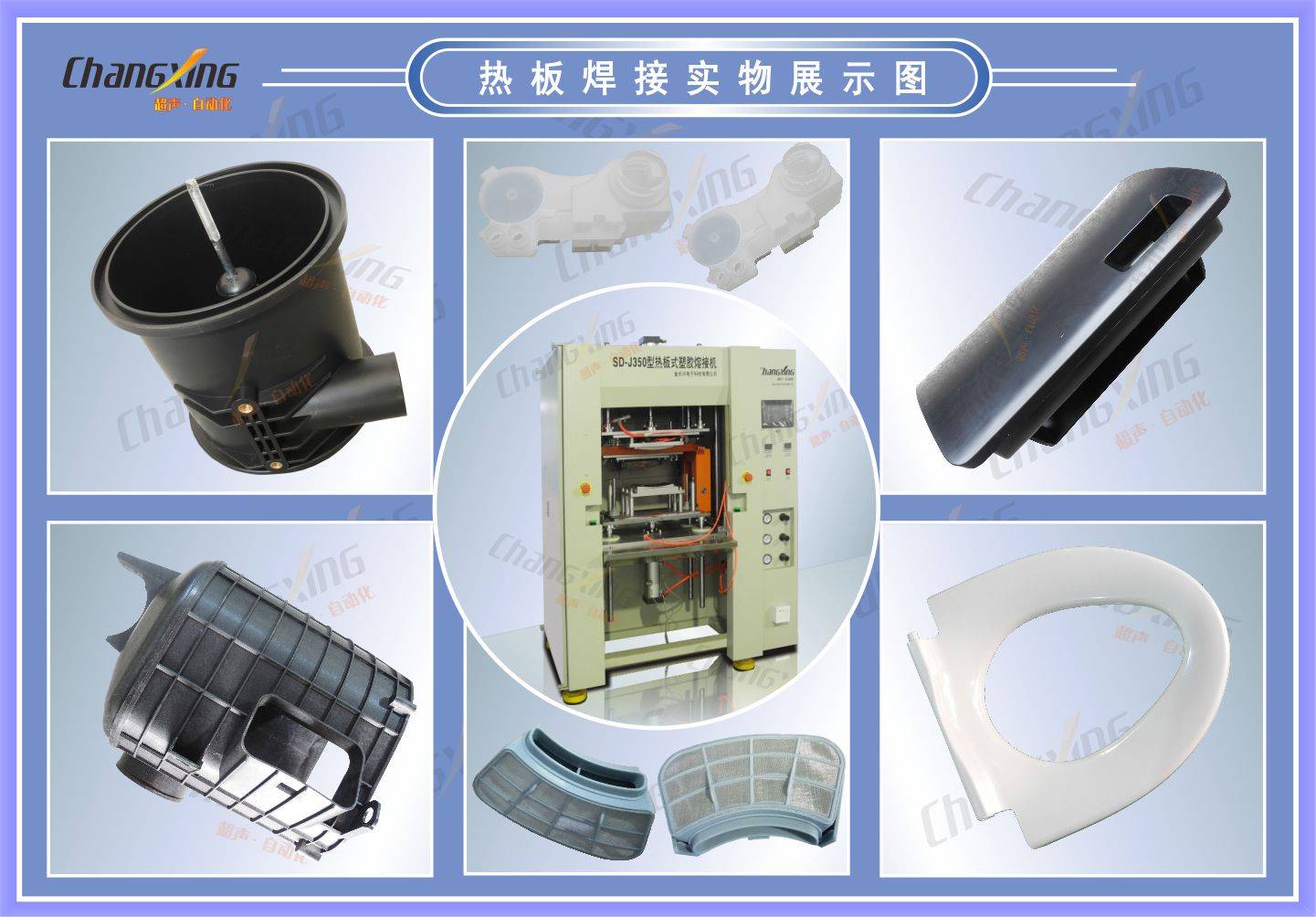

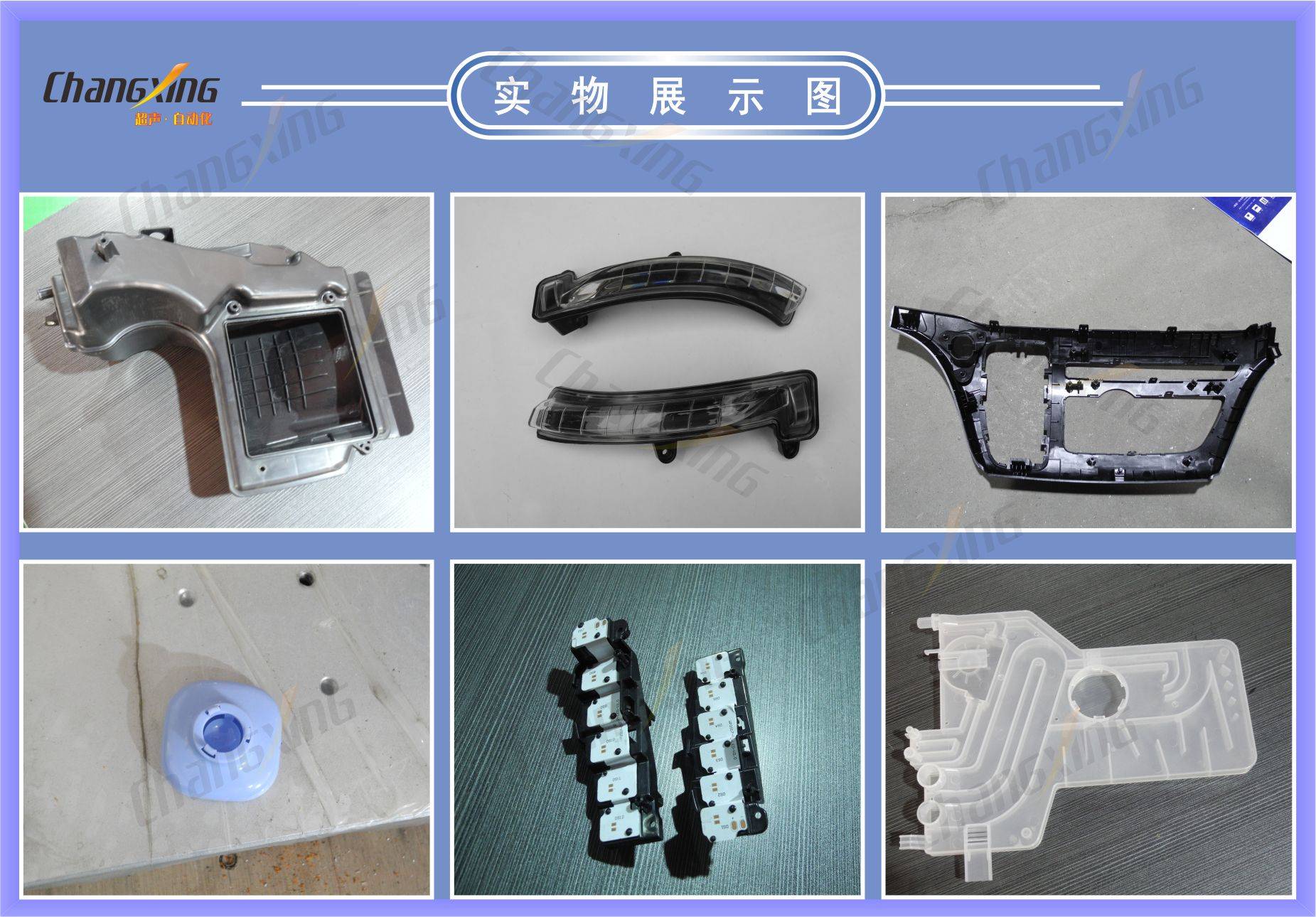

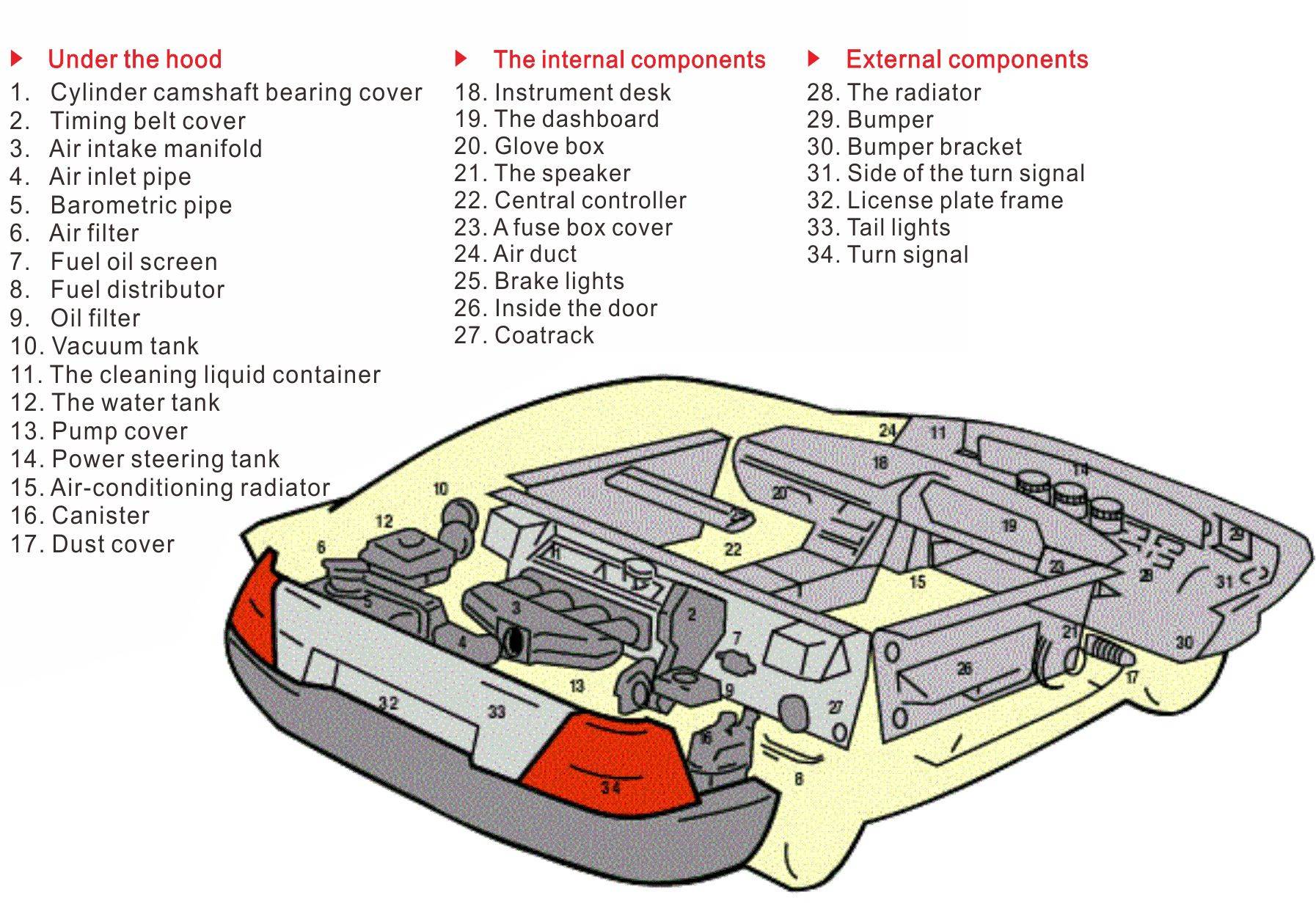

In modern vehicles, whether dressing (such as bumper, fender, wheel cover, guide plate, etc.), inner decoration, such as within the instrument panel, door board, vice dashboard, glove box cover, seat, back guard board, etc.), or function and structure (fuel tank cover, radiator water room, air filter, fan blades, etc.), the shadow of the plastic parts can be seen everywhere. Now, 100 kg of plastic material in modern car replaced the original should be 200 ~ 300 kg of traditional metal materials, weight loss effect is very outstanding, to save energy and reduce greenhouse gas emissions is of great significance. Such as car plastic intake manifold to replace metal can reduce the quality of 40% ~ 60%, and the normal flow resistance small, can improve the engine performance, and increase the combustion efficiency, reduce oil consumption, vibration noise reduction play a role. According to statistics, automotive plastic currently has dozens of varieties and dosage of the average car plastic have accounted for 5% ~ 10% of vehicle weight, along with the development of the automotive lightweight requirements and expand the application of automotive plastics technology, automotive plastic will further increase in the amount of bicycle.

Cars are divided into two types:

One is thermosetting plastic, which can withstand normal baking. One is thermoplastic plastic, which has the advantages of easy processing and quick processing. In automotive plastic, the top seven varieties of plastics materials and the proportion of roughly: 21% 21% 21% pp, pu, PVC, thermosetting composites 10.4% 8% 8% 8%, ABS, nylon, polyethylene.

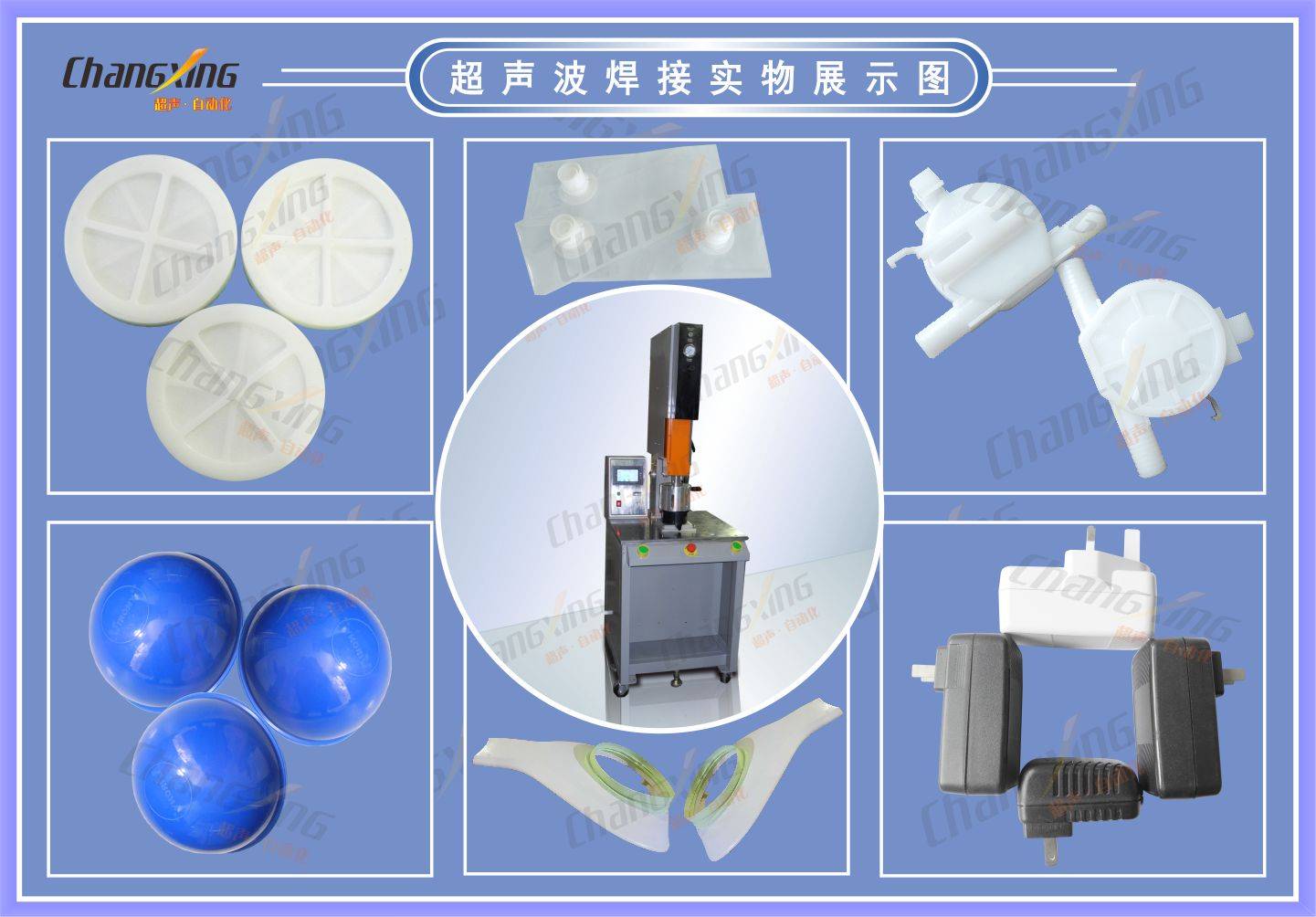

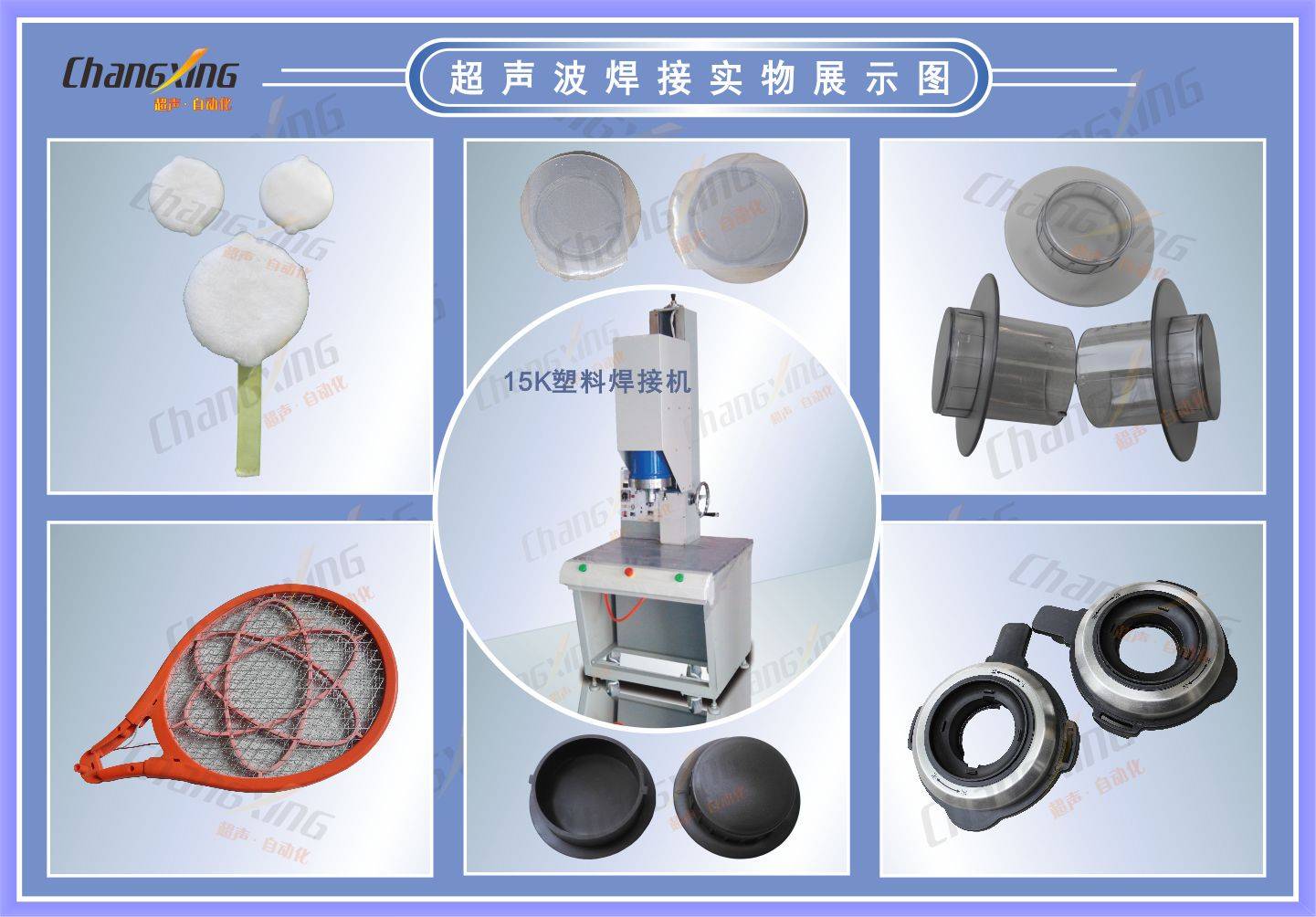

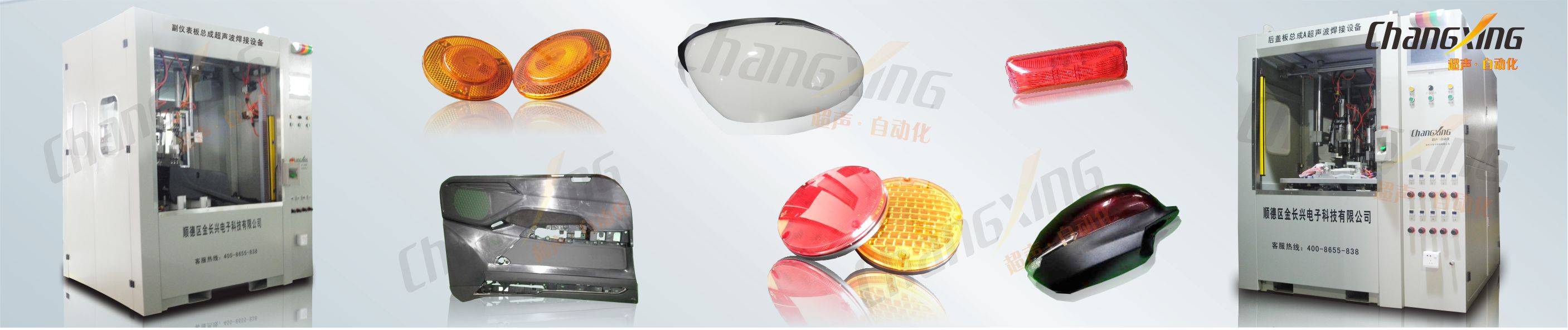

Plastic is a key part of its wider application. Plastic can be connected by mechanical fastening, bonding or welding. Fast connection speed, suitable for all plastics, but high cost, stress concentration, can not form sealing joint or obtain proper performance. Bonding can obtain excellent performance and high quality connectors, but difficult to operate, and need for joint and surface preparation, carefully and slowly, not suitable for mass production. And welding is economic, simple, fast and reliable, can form a static strength close to the parent metal joint, thus suitable for mass production, obtained more and more widely used in automobile industry. The level of plastic welding technology has become one of the indicators of the level of vehicle production technology and the development of new materials.

Various plastic welding methods in automobile industry:

Plastic welding limited to welding of thermoplastics, because only the thermoplastics can melt when heated or softening, and thermosets cannot be softened and remelting on heating.

Hot wind welding is similar to the oxygen acetylene welding of metal, except that the latter is heated by hot gas. Stream of hot gas welding process, from the welding torch (typical temperature is 200 ~ 300 ℃, the velocity of up to 15 ~ 60 l/min) and the filler rod and welding pieces of heat, soften to viscous material surface state, fill纱bout 3mm in diameter), welding the multipass welding when welding thick plate. Circular filling bar is a weakness in the weld process more hollow bubbles easily intercept in the weld, which reduces the strength, the problem can be solved by adopting triangle section welding rods. The typical materials for hot wind welding include polyvinyl chloride, polyethylene, polypropylene, organic glass, polycarbonate, polystyrene, polystyrene, nylon, ABS, etc. The main advantage of thermal welding is adaptability (flexibility), which can be used to process large, complex parts with simple portable devices. Hot air welding is suitable for the irregular structure, but it is slow, welding quality is largely dependent on the skills of the operator, so rarely used in mass production, but it applies Yu Xiuli operation.

position:home>Market Application

position:home>Market Application